Clues and Knowhow: Office Paper

von Florian Rigotti (geb. Heise)

Erschienen am 10. Oktober 2007 bei Druckerchannel.de, 13 Seite(n)

https://www.druckerchannel.de/artikel.php?ID=2069

Seite 11 von 13

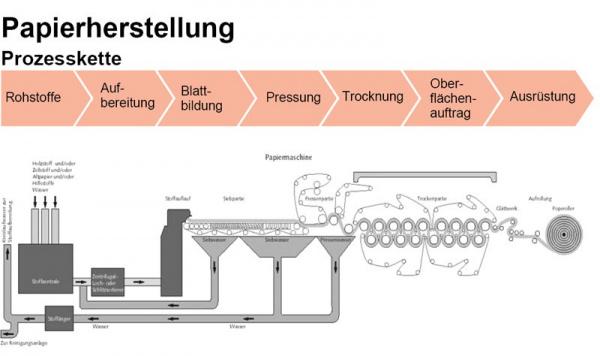

Knowhow 4: How Paper is made

Paper manufacture nowadays is a mainly computer-controlled process. Men take correcting actions only in eliminating damages or in monitoring.

The simplified depicted process begins with

- Rebuild of wood and/or straw in very small particles. Cleaning of recovered paper with subsequent milling.

- In a Pulper all ingredients are blended.

- The liquid homogeneous pulp flows into the wire section, which is a moving, endless wire mesh. Here the fibres start to spread and accumulate into a thin sheet, while part of the water is draining off.

- Follows the press section, where a series of presses squeeze more water out of the sheet.

- In the drying section it passes around several heated cast-iron cylinders, until it is down to the desired humidity. Now can follow a surface refinement.

- In the calander, an ironing kind process, to smooth the surface of the paper while it passes between rotating metal rollers.

- The Paperroller rolls up the finished paper.

Paper machine: More than 100 meters long.

Paper machine: More than 100 meters long.